The aerospace industry’s ongoing demand for high temperature / high strength materials systems and components requiring less weight have made Arrowhead Products a leader in the design of elastomeric and composite components. The resulting products combine both rigid and flexible sections in custom structural shapes. High flame resistance, low heat absorption, high flexibility, ultra light weight and superb thermal performance can be attained. Fiberglass batting, polyimide felt and flexible foam are used in composite muffler ducts for noise attenuation in high-temperature environments.

Composite Components

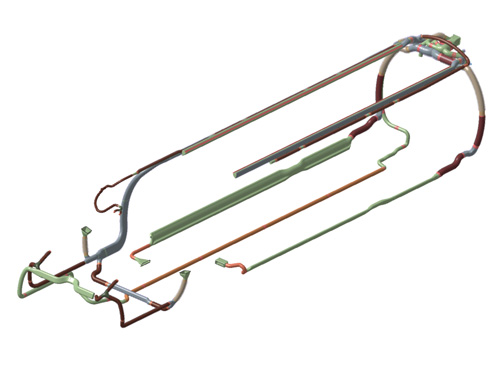

Arrowhead Products is a recognized leader in the design and manufacturing of flexible and semi-rigid composite components. Most of Arrowhead’s composite parts incorporate into their design the use of reinforcing fabrics coated with either elastomers or thermosetting resins that are cured to shape. The range of fabrics, elastomers, and resins includes all commercially available materials. In addition, Arrowhead has on its engineering staff, an R&D group that continually investigates and designs for use new materials that are often considered to be still in their early research-and-development stage. Other products include molded elastomeric parts.Low Pressure Systems

With our expertise in composite components, Arrowhead designs, manufactures, rig tests, and qualifies low pressure ducting systems for aircraft environmental control systems. With our experience in CATIA 4 and CATIA 5 modeling, 2D and 3D designs, computational fluid dynamics, and stress analysis along with a fully-staffed plaster pattern shop, engineering development lab and engineering test lab, Arrowhead is able to design, develop, test, and fabricate a fully functional low pressure ducting system.