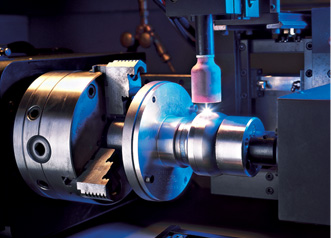

Arrowheads Products specializes in the manufacture of complex metallic and structural composite systems and components. Using Titanium, Inconel, CRES, Nimonic and other unique exotic alloys and materials that include Carbon Fiber, Kevlar and other laminates we provide the very best in machining, welding, forming, heat treatment, sheering, laser machining, curing (autoclave and ovens), assembly and all necessary NDT processes, all under one roof.

Arrowhead’s products have been aboard almost every aircraft and spacecraft in the past half century. The company’s advanced capabilities have earned it global recognition and an impressive list of customers in the commercial aviation, defense and space markets.

Arrowhead’s primary goal is to offer the most reliable products and the most responsive service to its customers by providing superior design with the assurance of quality and on time delivery

Arrowhead Products’ manufacturing success is based on decades of experience, utilization of proprietary manufacturing techniques and its continuous improvement efforts through 6s, kaizen, lean and six-sigma principles.

Our capabilities range but are not limited to:

- CNC Tube Bending

- CNC Routers

- Vacuum and Atmosphere Furnace

- Orbital Welding

- CNC Lathe Welding

- Laser Machining

- Waterjet Machining

- Gerber Cutting

- Autoclaves

- Bellows Forming Machines

- Stake Welding

- Resistance Seam Welding

- Short Run assembly weld fixtures

- Hydro-Forming

- Up to 500 Ton Forming Press Machines

- Complete Machine Shop

- Complete Tool and Die Shop

- Master Model and Plaster Shop