QUALITY

Our system is approved to the requirements of AS9100:2009 and ISO 9001:2008. All special processes performed in house are NADCAP and EASA certified. These special processes include heat treat, welding, non-destructive testing and chemical processing.

To view our certification documents, click on the images below

|

|

|

|

|

|

List of Quality Contacts

Dominic Ruiz, Vice President Quality Assurance

druiz@arrowheadproducts.net

Scott Clark A&P Accountable Manager/Repair Station Manager

sclark@arrowheadproducts.net

Raymond Morgan , Quality Systems Manager

rmorgan@arrowheadproducts.net

Quality Control

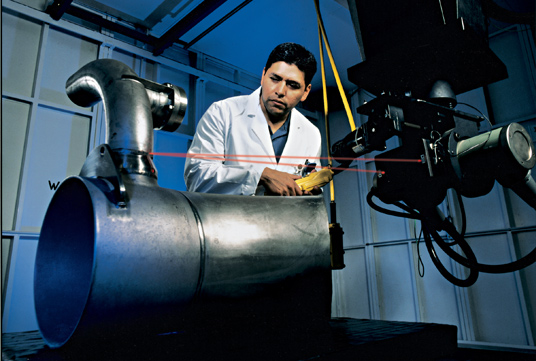

Quality is the key to success and it starts with a rigorous Quality Control System. From the beginning, we establish meticulous controls of all raw materials; manufacturing is monitored through various process control methodologies, and our operators are highly trained and certified in their field of expertise.

Our products undergo dimensional and mechanical inspection and if required we also provide:

- Helium Mass Spectrometer

- Dye Penetrant Inspection

- Particle Count Testing

- Environmental Test Chambers

- Thermal Bath Capability

- Mechanical Properties Testing

- Volume Testing

- Stroke Testing

- Spring Rate Testing

- Linearity Testing

- Hysteresis Testing

- Hardness Testing

- Product Verification Testing

- Metalgraphic Analysis

- Chemical Analysis

- Failure Analysis

- Property Management

- X-Ray Facilities

We design solutions for our customers and we understand that our customers may require special testing and quality requirements. We can meet those needs by developing a Quality Plan Review (QPR) to manage your product’s quality requirements.

Our Quality Policy:

| "Arrowhead Products is committed to meeting requirements and exceeding customer expectations in Quality, Delivery and Customer Satisfaction in parallel with Continual Improvement in all facets of its organization." |

| Return Of Products Policy |